Nuts

Nuts and custom solutions for industrial applications

Bea Group produces a wide range of heavy hex nuts designed for high-stress applications in industries such as oil&gas and petrochemical, marine, nuclear, rail, renewable and power generation. Our products, such as A194 7M heavy hex nuts and A194 8M heavy hex nuts, offer superior strength and reliability, particularly in demanding environments for structural applications.

These nuts are frequently used in conjunction with heavy-duty stud bolts to secure critical components, such as flanges, valves and pressure vessels. In recent years Bea has focused on the constant increase in demand of exotic materials and is now the market leader in the supply of bolting in nickel-alloys, stainless and super-duplex such as nuts 625, nuts 660a and nuts 718.

ASTM A453 660 /1.4980

Highly creep and corrosion resistant, precipitation hardening austenitic steel. Scaling resistance in air up to appr. 800°C.

UNS S32760 / ASTM A182 F55

Ferritic-austenitic stainless steel. Excellent corrosion resistance against general corrosion, stress corrosion cracking, corrosion fatigue, pitting, crevice and erosion corrosion and possessing very high mechanical strength properties.

ALLOY 718

High temperature, precipitation hardening, nickel-base alloy with particularly high hot strength and yield strength up to 750°C, and excellent creep behaviour up to 700°C. The markedly higher hot strength compare with normal hot work steels in particularly noticeable when used for hot work tools with high mechanical and thermal stresses.

ALLOY 625

Is a non-magnetic, corrosion and oxidation – resistance, nickel based alloy. High toughness and strength in the temperature range cryogenic to 1000°C. The alloy as excellent fatigue strength and stress corrosion cracking resistance to chloride ions.

ALLOY 925

Is as age-hardenable nickel-iron-chromium alloy. Is used in various applications requiring a combination of high strength and corrosion resistance.

MONEL 400

Is a solid-solution alloy that can be hardened only by cold working. It has high strength and toughness over a wide temperature range and excellent resistance to many corrosive environments. It is widely used in many fields, especially marine and chemical processing.

MONEL 500

Is a nickel-copper alloy with combines the excellent corrosion resistance of Monel 400 with the added advantages of greater strength and hardness. The increased properties are obtained by adding aluminium and titanium to the nickel-copper base by heating.

DUPLEX

Ferritic-austenitic stainless steel also referred to as DUPLEX STAINLESS STEELS, combine many of beneficial properties of ferritic and austenitic steels. Due to the high content of chromium and nitrogen, and often also molybdenum, these steels offer good resistance to localised and uniform corrosion. The duplex microstructure contributes to the high strength and high resistance to stress corrosion cracking.

SUPERDUPLEX

A Super Duplex stainless steel is a type of Duplex stainless steel with enhanced corrosion resistance which is categorised by its PREN being greater than 40. The Pitting Resistance Equivalent Number (PREN) is widely used as a means of comparing the relative corrosion resistance of different steel grades.

ASTM A193

Standard Specification for Alloy-Steel and Stainless Steel Bolting for High Temperature or High Pressure Service and Other Special Purpose Applications.

ASTM A320

Standard Specification for Alloy-Steel and Stainless Steel Bolting for Low-Temperature Service.

ASTM F467

Standard Specification for Nonferrous Nuts for General Use.

ASTM F468

Standard Specification for Nonferrous Bolts, Hex Cap Screws, Socket Head Cap Screws, and Studs for General Use.

Nuts technical specifications |

|

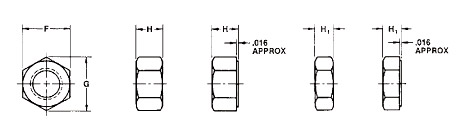

DIMENSIONS OF HEAVY HEX NUTS AND HEAVY HEX JAM NUTS in mm |

||||||||

|

ASME B 18.2.2 - TABLE 10 |

||||||||

|

Nominal Sizes |

Width Across Flats |

Width Across Corners |

Thickness |

Thickness |

||||

|

F |

G |

H |

H1 |

|||||

|

min |

max |

min |

max |

min |

max |

min |

max |

|

|

1/4 |

12,40 |

12,70 |

14,12 |

14,65 |

5,54 |

6,35 |

3,96 |

4,78 |

|

5/16 |

13,86 |

14,29 |

15,80 |

16,51 |

7,11 |

7,97 |

4,72 |

5,59 |

|

3/8 |

16,99 |

17,46 |

19,38 |

20,17 |

8,66 |

9,58 |

5,49 |

6,40 |

|

7/16 |

18,49 |

19,05 |

21,08 |

22,00 |

10,24 |

11,20 |

6,27 |

7,24 |

|

1/2 |

21,59 |

22,22 |

24,61 |

25,65 |

11,78 |

12,80 |

7,04 |

8,05 |

|

9/16 |

23,08 |

23,81 |

26,34 |

27,50 |

13,36 |

14,42 |

7,80 |

8,86 |

|

5/8 |

26,18 |

26,98 |

29,84 |

31,16 |

14,90 |

16,02 |

8,56 |

9,68 |

|

3/4 |

30,78 |

31,75 |

35,10 |

36,65 |

18,03 |

19,25 |

10,11 |

11,33 |

|

7/8 |

35,40 |

36,51 |

40,36 |

42,16 |

21,15 |

22,48 |

11,63 |

12,95 |

|

1 |

40,00 |

41,27 |

45,61 |

47,65 |

24,28 |

25,70 |

13,18 |

14,61 |

|

1 1/8 |

44,60 |

46,03 |

50,85 |

53,13 |

27,40 |

28,93 |

14,71 |

16,23 |

|

1 1/4 |

49,22 |

50,80 |

56,11 |

58,65 |

30,14 |

31,77 |

17,45 |

19,08 |

|

1 3/8 |

53,82 |

55,56 |

61,37 |

64,16 |

33,27 |

35,00 |

18,97 |

20,70 |

|

1 1/2 |

58,42 |

60,32 |

66,60 |

69,64 |

36,39 |

38,22 |

20,52 |

22,35 |

|

1 5/8 |

63,01 |

65,09 |

71,83 |

75,15 |

39,52 |

41,45 |

22,05 |

23,98 |

|

1 3/4 |

67,61 |

69,85 |

77,09 |

80,64 |

42,64 |

44,67 |

23,60 |

25,63 |

|

1 7/8 |

72,23 |

74,61 |

82,34 |

86,15 |

45,77 |

47,90 |

25,12 |

27,25 |

|

2 |

76,83 |

79,37 |

87,60 |

91,64 |

48,89 |

51,13 |

26,67 |

28,91 |

|

2 1/4 |

86,00 |

88,90 |

98,09 |

102,65 |

54,71 |

57,17 |

29,34 |

31,78 |

|

2 1/2 |

95,25 |

98,42 |

108,58 |

113,63 |

60,98 |

63,62 |

35,59 |

38,23 |

|

2 3/4 |

104,44 |

107,95 |

119,07 |

124,63 |

67,23 |

70,27 |

38,66 |

41,50 |

|

3 |

113,66 |

117,47 |

129,59 |

135,63 |

73,48 |

76,53 |

41,73 |

44,78 |

|

3 1/4 |

122,88 |

127,00 |

140,08 |

146,65 |

79,34 |

82,60 |

44,40 |

47,65 |

|

3 1/2 |

132,08 |

136,52 |

150,57 |

157,65 |

85,60 |

89,05 |

47,50 |

50,95 |

|

3 3/4 |

141,27 |

146,05 |

161,06 |

168,65 |

91,85 |

95,50 |

50,55 |

54,20 |

|

4 |

150,50 |

155,57 |

171,57 |

179,65 |

98,10 |

101,95 |

53,64 |

57,51 |

|

4 1/4 |

159,71 |

165,10 |

182,07 |

190,65 |

104,35 |

108,40 |

- |

- |

|

4 1/2 |

168,91 |

174,62 |

192,56 |

201,65 |

110,60 |

114,85 |

- |

- |

|

4 3/4 |

178,11 |

184,15 |

203,05 |

212,64 |

116,84 |

121,31 |

- |

- |

|

5 |

187,33 |

193,67 |

213,57 |

223,64 |

123,09 |

127,76 |

- |

- |

|

5 1/4 |

196,53 |

203,20 |

224,05 |

234,64 |

129,34 |

134,21 |

- |

- |

|

5 1/2 |

205,74 |

212,73 |

234,54 |

245,63 |

135,59 |

140,67 |

- |

- |

|

5 3/4 |

214,95 |

222,25 |

245,04 |

256,63 |

141,83 |

147,12 |

- |

- |

|

6 |

224,16 |

231,78 |

255,54 |

267,63 |

148,08 |

153,57 |

- |

- |

Dimensions in mm

Metric Range M6 - M100 |

|

|

|

DIMENSIONS OF HEX NUTS WITH METRIC COARSE AND FINE PITCH THREAD |

||||||||||

|

Nominal Size |

Width Across Flats |

Width Across Corners |

DIN 934 H=D |

DIN 934 |

DIN 936 |

|||||

|

F |

G |

H |

H1 |

H2 |

||||||

|

min |

max |

min |

max |

min |

max |

min |

max |

min |

max |

|

|

M 6 |

9,78 |

10,00 |

11,05 |

11,55 |

5,70 |

6,00 |

4,70 |

5,00 |

- |

- |

|

M 8 |

12,73 |

13,00 |

14,38 |

15,00 |

7,64 |

8,00 |

6,14 |

6,50 |

4,70 |

5,00 |

|

M 10 |

16,73 |

17,00 |

18,90 |

19,60 |

9,64 |

10,00 |

7,64 |

8,00 |

5,70 |

6,00 |

|

M 12 |

18,67 |

19,00 |

21,10 |

21,90 |

11,57 |

12,00 |

9,64 |

10,00 |

6,64 |

7,00 |

|

M 14 |

21,67 |

22,00 |

24,49 |

25,40 |

13,57 |

14,00 |

10,30 |

11,00 |

7,42 |

8,00 |

|

M 16 |

23,67 |

24,00 |

26,75 |

27,70 |

15,57 |

16,00 |

12,30 |

13,00 |

7,42 |

8,00 |

|

M 18 |

26,67 |

27,00 |

30,14 |

31,10 |

17,57 |

18,00 |

14,30 |

15,00 |

8,42 |

9,00 |

|

M 20 |

29,67 |

30,00 |

33,53 |

34,60 |

19,48 |

20,00 |

14,90 |

16,00 |

8,10 |

9,00 |

|

M 22 |

31,61 |

32,00 |

35,72 |

36,90 |

21,48 |

22,00 |

16,90 |

18,00 |

9,10 |

10,00 |

|

M 24 |

35,58 |

36,00 |

39,98 |

41,50 |

23,48 |

24,00 |

17,70 |

19,00 |

9,10 |

10,00 |

|

M 27 |

40,38 |

41,00 |

45,63 |

47,30 |

26,48 |

27,00 |

20,70 |

22,00 |

10,90 |

12,00 |

|

M 30 |

45,38 |

46,00 |

51,28 |

53,10 |

29,48 |

30,00 |

22,70 |

24,00 |

10,90 |

12,00 |

|

M 33 |

49,38 |

50,00 |

55,80 |

57,70 |

32,38 |

33,00 |

24,70 |

26,00 |

12,90 |

14,00 |

|

M 36 |

54,26 |

55,00 |

61,31 |

63,50 |

35,38 |

36,00 |

27,40 |

29,00 |

12,90 |

14,00 |

|

M 39 |

59,26 |

60,00 |

66,96 |

69,30 |

38,38 |

39,00 |

29,40 |

31,00 |

14,90 |

16,00 |

|

M 42 |

64,26 |

65,00 |

72,61 |

75,00 |

41,38 |

42,00 |

32,40 |

34,00 |

14,90 |

16,00 |

|

M 45 |

69,26 |

70,00 |

78,26 |

80,80 |

44,38 |

45,00 |

34,40 |

36,00 |

16,90 |

18,00 |

|

M 48 |

74,26 |

75,00 |

83,91 |

86,50 |

47,38 |

48,00 |

36,40 |

38,00 |

16,90 |

18,00 |

|

M 52 |

79,26 |

80,00 |

89,56 |

92,40 |

51,26 |

52,00 |

40,40 |

42,00 |

18,70 |

20,00 |

|

M 56 |

84,13 |

85,00 |

95,07 |

98,10 |

55,26 |

56,00 |

43,40 |

45,00 |

20,70 |

22,00 |

|

M 60 |

89,13 |

90,00 |

100,72 |

103,90 |

59,26 |

60,00 |

46,40 |

48,00 |

22,70 |

24,00 |

|

M 64 |

94,13 |

95,00 |

106,37 |

109,70 |

63,26 |

64,00 |

49,10 |

51,00 |

24,70 |

26,00 |

|

M 68 |

99,13 |

100,00 |

112,02 |

115,50 |

67,26 |

68,00 |

52,10 |

54,00 |

24,70 |

26,00 |

|

M 72 |

104,13 |

105,00 |

117,67 |

121,25 |

71,26 |

72,00 |

56,10 |

58,00 |

26,70 |

28,00 |

|

M 76 |

109,13 |

110,00 |

123,32 |

127,00 |

75,26 |

76,00 |

59,10 |

61,00 |

28,70 |

30,00 |

|

M 80 |

114,13 |

115,00 |

128,97 |

132,80 |

79,26 |

80,00 |

62,10 |

64,00 |

30,40 |

32,00 |

|

M 85 |

119,13 |

120,00 |

134,62 |

138,60 |

84,13 |

85,00 |

66,10 |

68,00 |

32,40 |

34,00 |

|

M 90 |

129,00 |

130,00 |

145,77 |

150,10 |

89,13 |

90,00 |

70,10 |

72,00 |

34,40 |

36,00 |

|

M 95 |

134,00 |

135,00 |

151,42 |

155,90 |

94,13 |

95,00 |

74,10 |

76,00 |

36,40 |

38,00 |

|

M 100 |

144,00 |

145,00 |

162,72 |

167,40 |

99,13 |

100,00 |

78,10 |

80,00 |

38,40 |

40,00 |

|

M105 |

147,50 |

150,00 |

168,37 |

173,21 |

102,80 |

105,00 |

81,80 |

84,00 |

40,40 |

42,00 |

|

M110 |

152,50 |

155,00 |

172,32 |

178,98 |

107,80 |

110,00 |

85,80 |

88,00 |

42,40 |

44,00 |

|

M115 |

162,50 |

165,00 |

185,32 |

190,53 |

112,80 |

115,00 |

89,80 |

92,00 |

44,40 |

46,00 |

|

M120 |

167,50 |

170,00 |

190,97 |

196,30 |

117,80 |

120,00 |

93,80 |

96,00 |

46,40 |

48,00 |

|

M125 |

177,50 |

180,00 |

200,57 |

207,85 |

122,50 |

125,00 |

97,80 |

100,00 |

48,40 |

50,00 |

|

M130 |

180,40 |

185,00 |

207,75 |

213,62 |

127,50 |

130,00 |

101,80 |

104,00 |

50,10 |

52,00 |

|

M135 |

185,40 |

190,00 |

213,40 |

219,40 |

132,50 |

135,00 |

105,80 |

108,00 |

52,10 |

54,00 |

|

M140 |

195,40 |

200,00 |

220,80 |

230,95 |

137,50 |

140,00 |

109,80 |

112,00 |

54,10 |

56,00 |

|

M145 |

205,40 |

210,00 |

236,00 |

242,49 |

142,50 |

145,00 |

113,80 |

116,00 |

56,10 |

58,00 |

|

M150 |

205,40 |

210,00 |

236,00 |

242,49 |

147,50 |

150,00 |

117,80 |

120,00 |

58,10 |

60,00 |

Dimensions in mm